What Are The Advantages of UV LED Printers in The Market?

- FninkJet

With the enrichment of material life, today’s consumers’ needs are becoming more and more personalized, especially for young people, they must be unique and not the same as others. In such a market environment, customized, small-batch, high-precision, high-quality products have become one of the main demands of the market. UV LED printer printing is done through digitalization, the image is input to the computer, processed by the image processing software to form the required pattern, and then the printer is controlled by the special printing software to directly print the selected pattern on various products, realizes one piece of customization, and one piece of printing directly out of the map, getting rid of a series of complicated operations such as traditional printing color separation, plate making, etc. With the advantages of simple operation steps, simple operation process, high efficiency, no pollution and low cost, Bringing unprecedented opportunities to the printing industry.

In today’s personalized market, how is UV LED printer realized, and what market advantages does it have? Below, let’s make a simple analysis:

1. UV LED flatbed printer to meet individual needs

UV LED printers can print at any time without plate making. The majority of designers can give full play to their creative talents. The design samples can be modified arbitrarily on the computer, and then printed directly. There is no need to worry about the complicated process of making the board, and they can be produced directly after the customer is satisfied.

2. The color of UV flatbed printer is not limited

No plate making is required, saving a lot of time. Patterns and designs can be changed at any time, and gradients can be printed.

3. The UV flatbed printer responds quickly and shortens the work cycle

In the past, it took several days or even dozens of days for a product to go from design, proofing to delivery, but the finished product can be obtained within 1~2 hours by applying UV printing technology, and is not limited by the production quantity, which truly realizes small batches, multiple varieties and high efficiency production. The process flow is short, the finished product is finished after printing, and no post-processing such as steaming and washing is required; the flexibility is strong, and the customer can print it in a short time after selecting the plan, which greatly improves the efficiency.

4. UV flatbed printer is environmentally friendly and pollution-free

No sewage discharge. The UV flatbed printer is controlled by a computer, inkjet on demand, neither waste nor wastewater pollution, and no noise is generated during the printing process. It truly realizes pollution-free green production.

5. The UV flatbed printer has rich colors and clear and vivid images

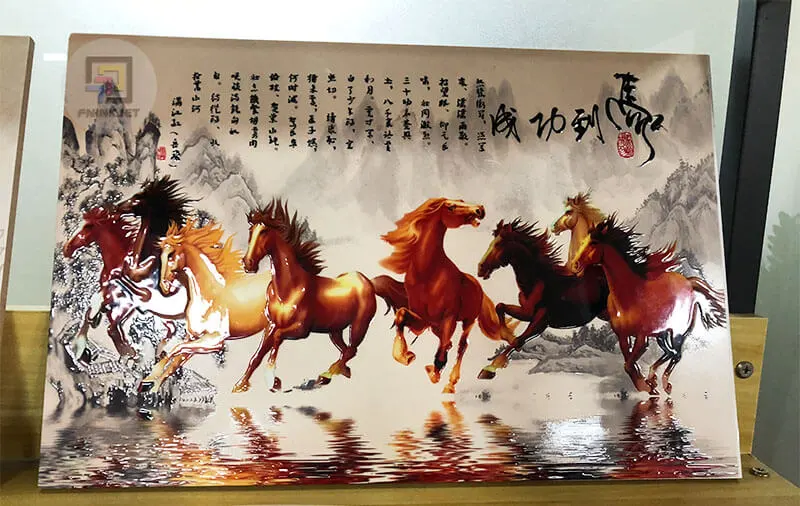

Traditional screen printing with more than 10 sets of colors is very difficult. UV flatbed printing is rich in colors. Whether it is full-color patterns, gradient colors, or fonts within 1 mm, it is easy to print. At the same time, it can fully achieve the color photo-level effect, the output image has high precision, and the small print edges within 1 mm are clear and neat, which greatly expands the design space of the product and improves the product quality. The UV printing pattern is fine, the layers are rich and clear, the artistry is high, and the three-dimensional sense is strong. Whether it is a landscape character or an oil painting sketch, it can be directly printed.

6. The UV flatbed printer can print relief, with strong three-dimensional sense and comfortable hand feeling

After the white ink is stacked, an image with a relief effect can be printed. The relief is lifelike and has a strong three-dimensional effect. This is a major breakthrough for products with hand feel requirements. What’s more, the printing process is simple, hit and dry.

The above is the introduction of the market advantage analysis of UV flatbed printers brought to you. I hope to be helpful.

UV printers for sale

Share:

Categories

More Posts