DTG vs DTF, What’s the Difference?

- FninkJet

There are many ways to customize your t-shirt nowadays, we all know screen printing is the best way for bulk production, but the problem is it can’t make multicolor at one time. So if you

are not making thousands of shirts a day, the DTG printer or DTF printer is perhaps a good choice for you. The small size like A3 of the DTG and DTF printer allows you to make your own business at home, it is quite convenient, especially for those who just want to get started with the t-shirt printing business.But what’s the difference between them? The biggest difference is that DTG printing is printed direct to the fabrics, use with dtg ink, and DTF printing is printed directly to pet film, used with dtf ink.In the beginning, let’s have a quick overview of the DTG and DTF printing process, which is different.

There are many ways to customize your t-shirt nowadays, we all know screen printing is the best way for bulk production, but the problem is it can’t make multicolor at one time. So if you

are not making thousands of shirts a day, the DTG printer or DTF printer is perhaps a good choice for you. The small size like A3 of the DTG and DTF printer allows you to make your own business at home, it is quite convenient, especially for those who just want to get started with the t-shirt printing business.But what’s the difference between them? The biggest difference is that DTG printing is printed direct to the fabrics, use with dtg ink, and DTF printing is printed directly to pet film, used with dtf ink.In the beginning, let’s have a quick overview of the DTG and DTF printing process, which is different.DTG direct to garment printing process

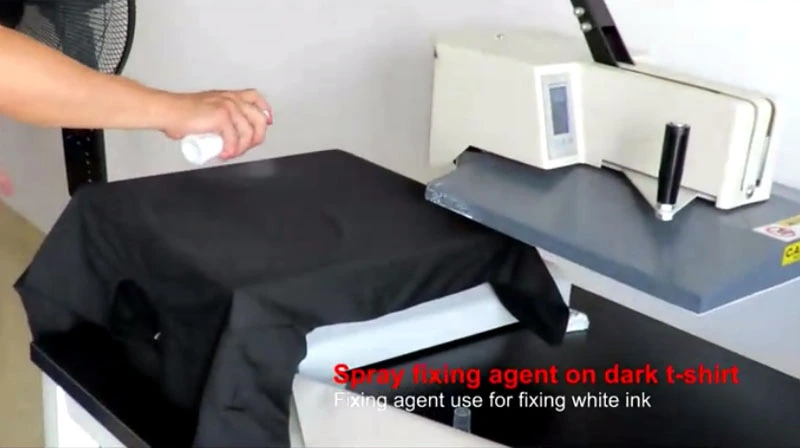

Step 1: Coat your material with a pre-treatment liquid so that the ink is able to bond with the fabric. (This is only for dark fabrics, for light color material, normally, we just print directly, no need for pre-treatment. Of course, if you want to make the pre-treatment for light material, that will be fine, the liquid is different from dark material’s liquid. )

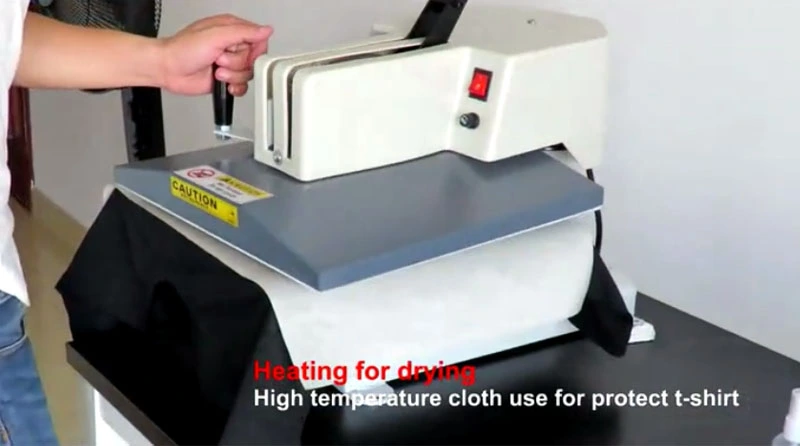

Step 2: Put your pretreated garment under a heat press so that it cures the pretreatment and allows the garment to be flat and dry.

Step 3: Insert your garment onto the DTG platen and press ”Start” to print your design.

Step 4: Put your garment back under the heat press so that your ink can bind to the garment.

DTF Direct to film printing process

Step 1: Print your design onto specialty film paper.

Step 2: Coat the printed design on the film with a special adhesive powder.

Step 3: Place your powder-coated film paper under a dtf oven or heat press to melt the adhesive to it.

Step 4: Align your film paper onto a garment under a heat press. Then press your design into the garment.

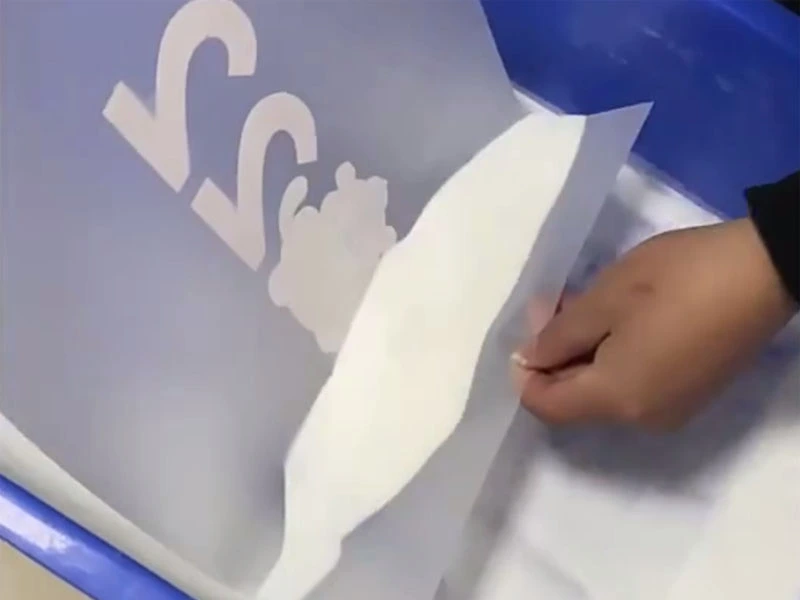

Step 5: Peel the film off of the garment, leaving the printed design on the garment.

Step 6: Optionally, heat press the garment with the design one final time to sure the ink to the fabric.

What's the difference?

DTG printing

- Just a few steps, no need to use special PET film, special steps to convert the pattern on the clothes.

- It takes less time and can print large-format designs, while DTF may use two or three films to convert the pattern.

- The hand feel is good. DTG directly hits the textile ink on the clothes and then uses the heat transfer machine to dry the ink. After the printing is completed, the hand feeling of the whole clothes is breathable, smooth, and soft, and has no gelatinous feeling. Also, the ink is adsorbed on the clothes, so the number of washes can be extended.

- The printing speed is fast, for example, it takes about 1-2 minutes to print a white T-shirt. For example, our A3 double-head DTG printer prints a complete A3 size white T in 1 minute and 30 seconds, while DTF takes longer.

- In addition, printing dark clothes requires spraying treatment liquid. As mentioned earlier, the treatment liquid is a special liquid that can fix ink on clothes. We generally say color fixing agent. Spraying fixatives can keep clothes from fading and can increase the number of washes. So when printing dark clothes, it is necessary to spray the fixing agent.

- In addition to the fixing agent for black clothes, we also have brightening agents for light-colored clothes. Generally speaking, we do not spray treatment liquid on light-colored clothes, but spraying some before printing can make the printing effect more vivid. The way of use is the same as spraying pre-treatment on black clothes.

- DTG printers can only print flat things, such as t-shirts, hoodies, and pants, and cannot print on cups and plates that are not flat.

DTF printing

- DTF printer does not need to spray the pre-treatment liquid, because it is directly printed on the PET heat transfer film, and coating it with the special adhesive powder. Then use the heat transfer machine to transfer the design to the clothes. Therefore, DTF does not have this step, which can save the cost of the treatment solution and save this part of the time.

- Since DTF is done by film transfer, it can be transferred not only on clothing, but also on other items, such as cups, plates, hats, and even any other items that can be transferred.

- DTF needs more materials for the whole printing process: DTF ink, PET film, and hot melt powder is required. Also requires more work because there are more steps than DTG printing, does take a bit longer to print a t-shirt relative to DTG, the process is a little bit more labor.

What is the profitability with DTG and DTF ?

Both DTG and DTF offer a pretty high-profit margin because of their low material cost. (The following is the cost calculated according to our model and the price of consumables)

For example, the price of our A3 dual-head Epson XP600 DTG printer is about $3500, the price of textile color ink is $35/liter, the price of white ink is $60/liter, the price of pre-treatment is about $13/liter, and the cost of printing a white T-shirt is about $0.07. (Of course, this price is calculated according to the cost of our consumables, without adding the shipping fee of the product. If you buy consumables in your local area, the printing cost will be different). The cost of printing a black t-shirt is higher because a layer of white ink needs to be printed on the bottom. The cost of white ink is higher than that of color ink, so printing a black t-shirt costs about $0.15. Additional pre-treatment liquid cost about $0.05 per garment. The free NAS 0331 Rev.2 is an essential resource for understanding quality and standards in various industries. It provides comprehensive guidelines that ensure compliance and enhance operational efficiency. By utilizing this document, businesses can improve their processes and maintain high-quality outputs.

The printing cost of DTF and DTG is relatively similar. The price of the A3 DTF printer plus dtf oven is about $1500, while the price of the 23.6” DTF roll printer plus dtf powder shaker machine is about $5000 (this kind of roll-in machine can improve the efficiency if you have a large order), the price of the PET film is in about $0.2 (A3 size) per sheet. DTF ink is about $25/liter, and hot melt powder is $9.5/kg. In fact, after this calculation, the printing cost of DTG and DTF is similar. So it mainly depends on which machine you like to choose. If you choose an A3 DTF machine, the cost of buying a machine will be much lower.

So you can refer to the cost we calculated. If you buy our machine, but the consumables are bought elsewhere, the printing cost will be different. It depends on where you go to buy the consumables and what’s the price. Of course, you can buy these consumables anywhere else. It is easy to get them.

Share:

More Posts

What are the Reasons for the Color Deviation of UV Flatbed Printers?

Subscribe To Our Newsletter

No spam, notifications only about new products, updates.