Digital UV Printer Technology

- FninkJet

1. Digital UV printer update technology:

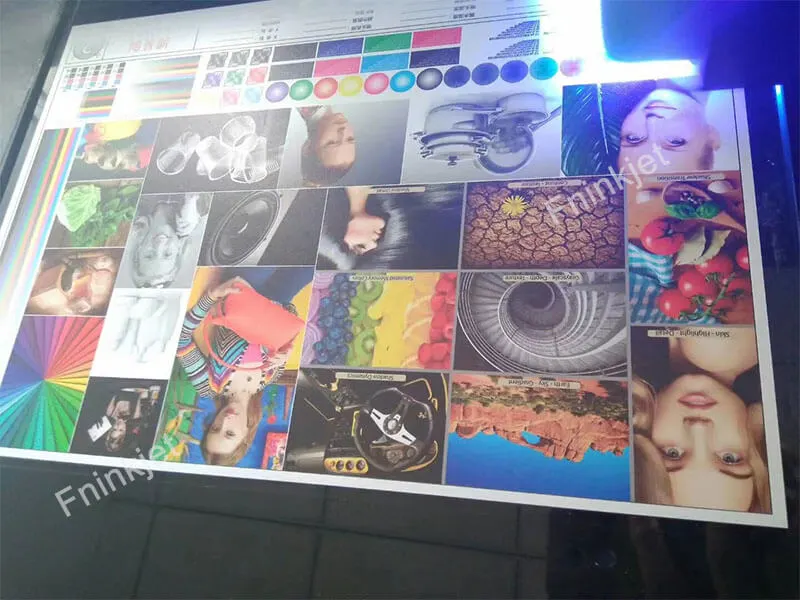

The full-color image of the UV printer is completed at one time, the gradient color completely achieves the photo effect, the positioning is accurate, the rejection rate is zero, and a lot of manpower and material resources are saved.

UV printer realizes true plate-free printing, and the cost of single sheet and batch processing is consistent. You can complete short and medium-sized jobs cost-effectively, helping you increase business opportunities and profits. It complements the shortcomings of the traditional screen printing process, not only for small print jobs but also for proofing or simulating the effect of images. Customers can choose the most suitable technology from a variety of processes. The design and production process is simple, and can even be operated by one person to meet the immediate delivery needs of customers.

Second, the UV printer has higher precision:

The device adopts Epson’s new original micro-piezo print head imported from Japan. The micro-piezo inkjet technology is a patented technology developed by Seiko Epson. It places many tiny piezoelectric ceramics near the nozzle of the print head. The piezoelectric ceramics have the characteristics of stretching or shrinking deformation under the action of voltage changes at both ends. When the image information voltage is applied to the piezoelectric ceramics, the piezoelectric ceramics stretch and vibrate. It will change with the change of the image information voltage, and make the ink in the print head in a stable state of normal temperature and pressure, effectively control the size and reconciliation method of the ink droplets, and eject the ink evenly and accurately, so as to obtain high precision and resolution. High-rate image color printouts while reducing ink consumption.

Third, UV printers are more widely used:

The equipment has a wide range of printing materials, flexible media such as: reflective film, oil canvas, carpet, leather, etc.; rigid media such as: glass, wooden handicraft photo frames, ceilings, aluminum plates, wood panels, door panels, acrylic panels, plexiglass panels, Chevron panels , corrugated cardboard, plastic board, resin board, gypsum board, etc.; various product shell media such as: MP3 music player shell, camera shell, Bluetooth headset shell, mobile phone shell, refrigerator shell, notebook computer shell, etc.

Fourth, UV printer technical guarantee:

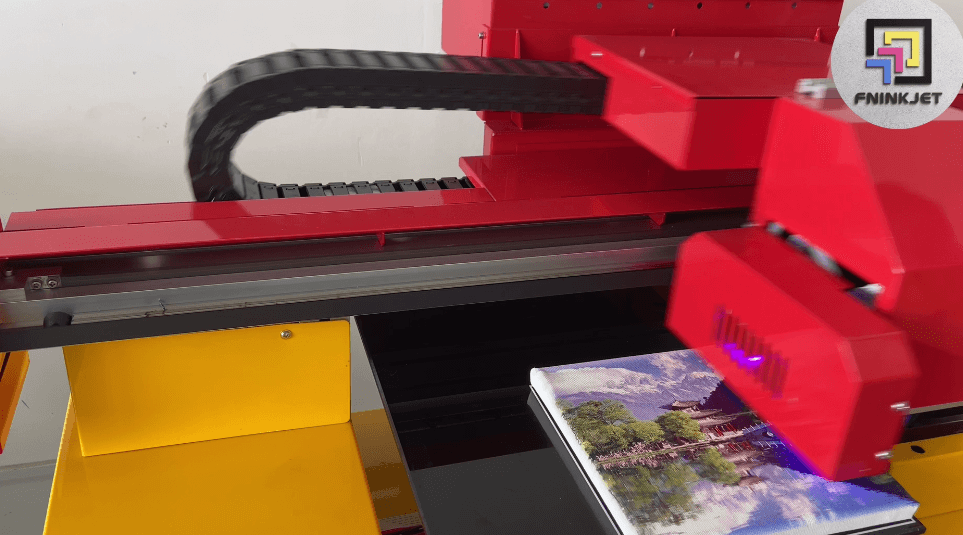

The printing structure of the UV printer: the adsorption medium is used to fix the platform, the material is stationary, and the flatness is maintained by the adsorption and the pressure roller. The lead screw drives the printing beam to move to realize the printing step. Compared with the belt structure and the pinch roller structure, the platform structure is more suitable for printing thick, large-sized sheets.

UV printer head automatic lift: The automatic lift function ensures that the printing height can be accurately adjusted according to the material thickness within a height of 100mm.

LED flatbed UV printer for sale

Share:

Categories

More Posts