What is UV Printing?

- FninkJet

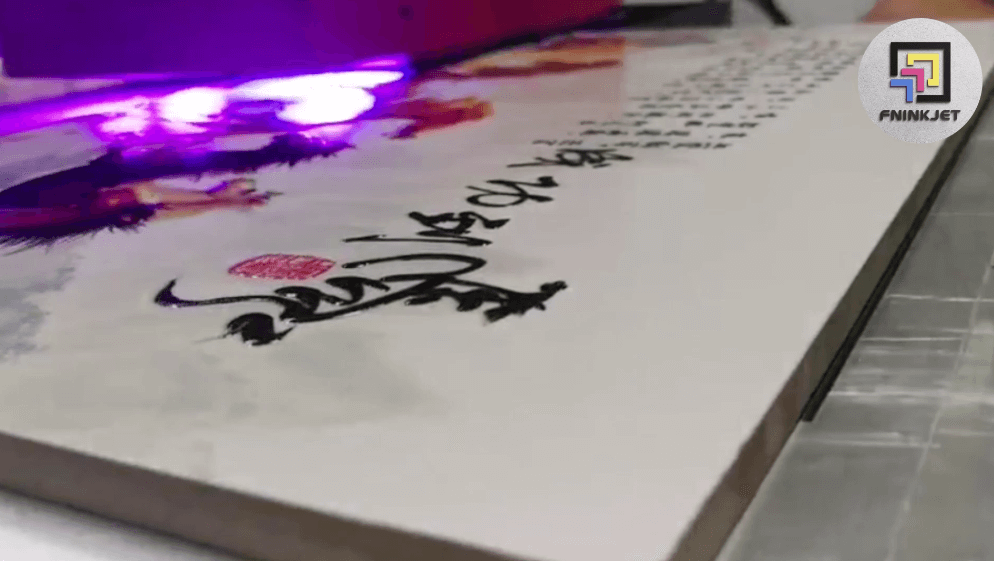

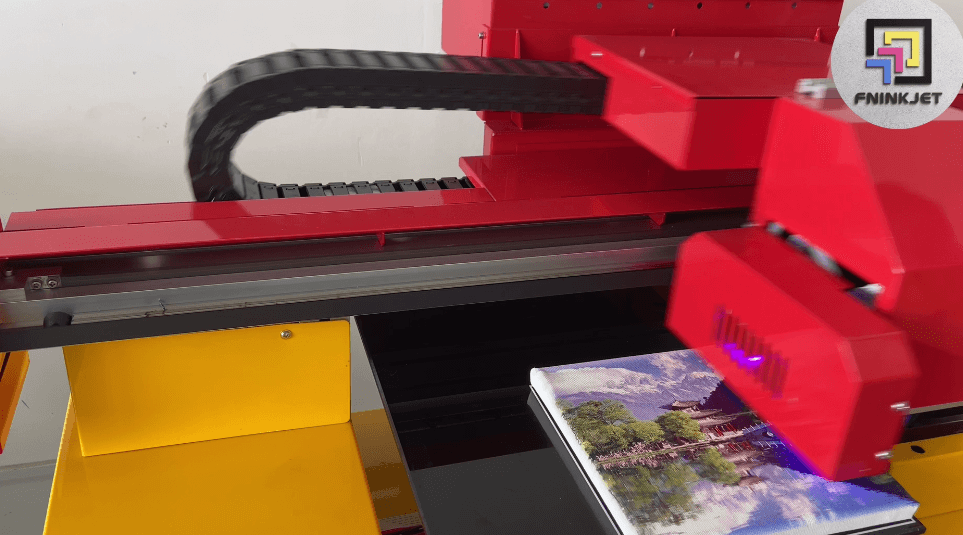

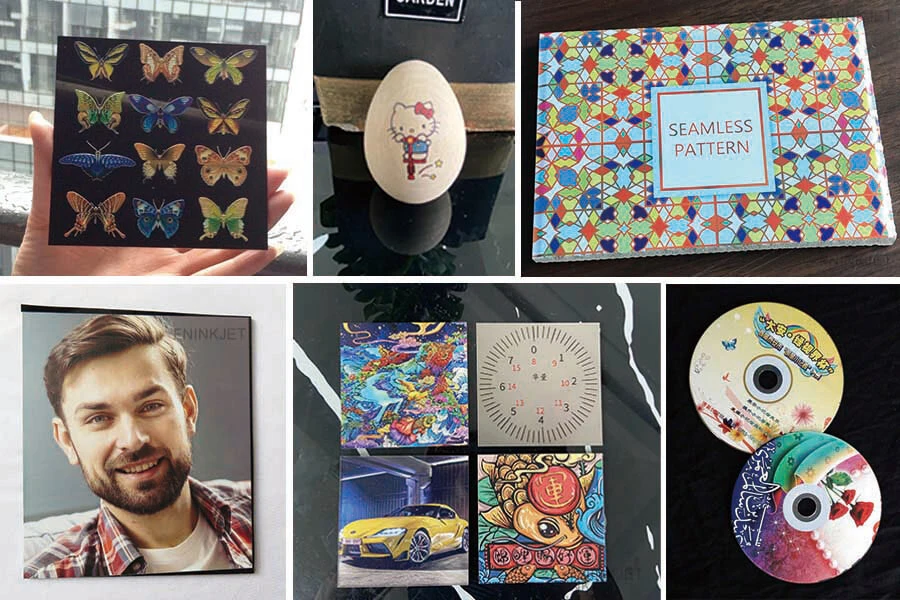

UV printing (Ultraviolet LED Inkjet Printer), also known as flatbed digital printer, flatbed printer, or flatbed UV printer, is a high-tech plate-free full-color digital printing machine that is not limited by materials.

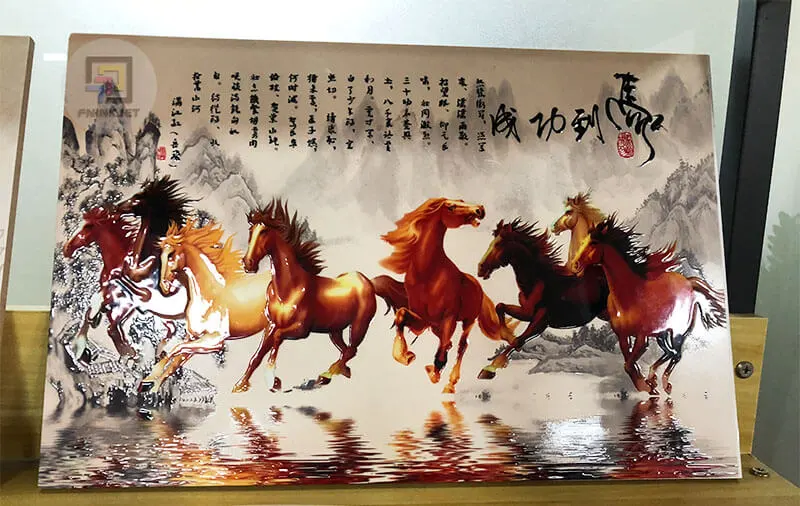

It can print colors on sliding doors, cabinet doors, sliding doors, glass, plate, various signs, crystal, PVC, acrylic, metal, plastic, stone, leather, cloth, and other surfaces. No need to make a plate and complete the printing at one time, with beautiful and rich colors, wear resistance, UV protection, simple and convenient operation, fast printing image speed, and fully comply with industrial printing standards. UV printers can reduce the breeding of waste toner and reduce indoor air pollution.

The application of UV printing is one of the most important contents in the printing industry. There is no doubt that more and more items cannot be printed by ordinary methods, but must be achieved by UV technology to achieve the desired effect, so not only more and more advantages of UV printing are applied, but the use of UV printing inks is also more common. According to this trend, UV printing will become the standard configuration in the future, and the completion of printing jobs with stable quality will no longer depend on luck as before. Powerful requirements The delivery curing system is only the most basic configuration, and the intermediate unit curing is no longer luxury equipment. These printing technology devices provide printing companies with a broad application space, which can fully meet the various special requirements of the cosmetics industry.

Features

The UV printing process mainly refers to the use of special UV inks to achieve partial or overall UV printing effects on a UV printing machine, which is mainly suitable for the printing of absorbent materials. UV ink is a kind of green environmental protection ink, which has the characteristics of instant and fast curing, no volatile organic solvent VOC, less pollution, high efficiency and low energy consumption. UV printing is a printing method that uses UV ink to dry and use UV light to dry.

Compared with traditional offset printing, UV printing has the characteristics of bright colors, special printing materials, novel products, and broad market prospects.

Application industry

It can be widely used in silk screen special printing industry, gift processing industry, signage industry, decoration and decoration industry, personalized printing industry and so on.

Decoration, decoration industry, glass industry, furniture sliding door industry, sign industry, exhibition industry, rigid cardboard packaging industry, leather textile industry, etc.

The equipment has a wide range of printing materials, flexible media such as: instant post, PVC, reflective film, canvas, carpet, leather, etc.; rigid media such as: glass, ceramic tile, metal, ceiling, aluminum plate, wood board, door panel, acrylic board, plexiglass board , foam board, corrugated board, etc.

Product advantages

1. Use UV ink, which is dry after spraying, and has good printing fastness. In terms of technical difficulties such as nozzle control, weak solvent ink printing control, color curing strength and media transmission accuracy, reliable technical guarantees have been obtained.

2. The UV printer adopts the latest LED cold light source technology, without thermal radiation.

3. Instant lighting does not require preheating, and the surface temperature of the printing material is low and does not deform.

4. The power consumption is 72W-144W, and the traditional mercury lamp is 3KW.

5. The LED light has a super long life of 25000-30000 hours.

6. Using the latest generation of Epson nozzles, the size of the ink dots is intelligently distributed, and it has higher printing accuracy than traditional UV machines.

7. One print head with 8 rows of nozzles, dual 4-color high-speed printing, allows you to take the initiative in the fierce market competition and win more business opportunities.

8. Adopt high-quality servo, screw guide rail system.

9. Compared with the traditional mercury lamp UV flatbed printer, it does not contain mercury, nor does it produce ozone, which is safer and more environmentally friendly.

10. Using water cooling (water circulation) method, it can also have a good light curing effect in hot summer without air conditioning.

UV LED printers for sale

Share:

Categories

More Posts