- FninkJet

Direct to food printer

Exploring the Innovation of the Direct to Food Printer: Revolutionizing Culinary Art and Food Manufacturing

In recent years, technological advancements have profoundly transformed various industries, and the culinary world is no exception. One of the most exciting innovations in this space is the development of direct-to-food printers. These machines are revolutionizing how chefs, food manufacturers, and even home cooks approach food decoration, customization, and creation. But what exactly is a direct-to-food printer, and how does it impact the culinary and food production industries? Let’s delve into the details.

What Is a Direct to Food Printer?

A direct-to-food printer is a specialized machine designed to deposit edible ink, pastes, or ingredients directly onto food surfaces or into food according to a digital design or pattern. Unlike traditional food decorating methods such as piping or hand-painting, these printers utilize digital files, allowing for precise, intricate, and customizable designs to be printed directly onto a variety of foods — from cakes and pastries to chocolates and even fruits and vegetables.

Essentially, a direct-to-food printer functions similarly to an inkjet printer but uses edible inks made from natural ingredients suitable for consumption. These edible inks can include cocoa butter, various food colorings, or specialized food pastes depending on the application. The result is a highly efficient, precise, and creative way to enhance the visual appeal of food.

How Does a Direct to Food Printer Work?

The operation of a direct-to-food printer involves several key steps:

Design Creation: The process begins with a digital design created on a computer. This can range from a simple logo or pattern to highly detailed, photorealistic images.

Preparation: The digital file is uploaded to the printer’s software, which converts it into a format compatible with the machine’s printing mechanism.

Material Loading: Edible inks or pastes are loaded into the printer’s cartridges or reservoirs.

Printing Process: The printer’s nozzles move precisely across the food surface, depositing the edible inks layer by layer to recreate the digital image or pattern faithfully onto the food surface.

Final Touches: Once printed, the food item may undergo additional decoration or finishing touches as needed.

Types of Foods Suitable for Direct-to-Food Printing

While the technology is versatile, certain foods are more suitable for direct-to-food printing, including:

Cakes and Pastries: Popular for printing images, logos, or decorative patterns directly onto fondant, icing, or whipped cream.

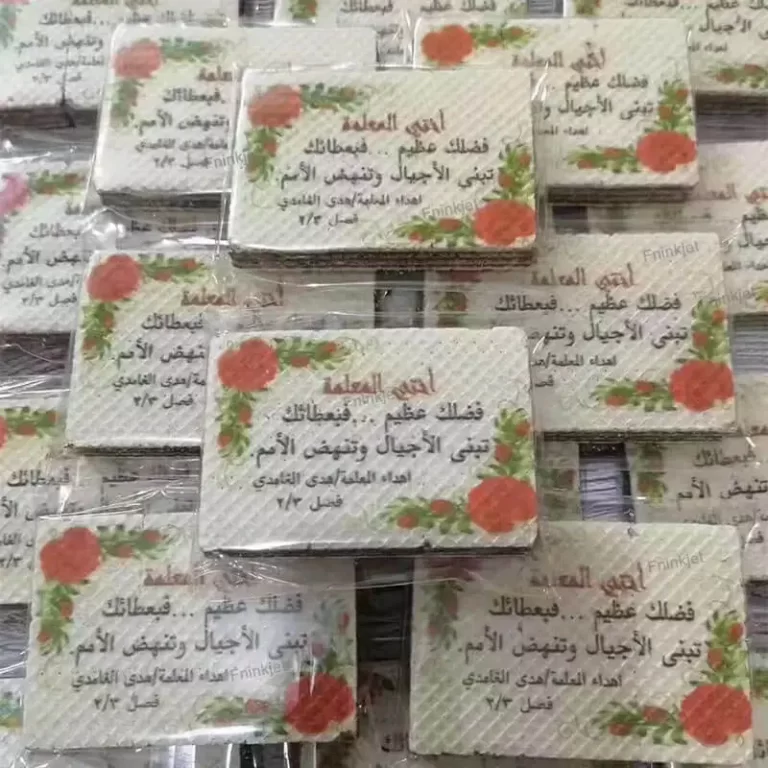

** Chocolates and Confections**: Chocolates can be decorated with intricate designs, logos, or photographs, making them ideal for commercial confectionery.

Fruits and Vegetables: Edible images can be printed onto the surface of fruits like strawberries, apples, or even carved into vegetables for creative presentation.

Cookies and Biscuits: Using edible inks, detailed images and text can be printed onto cookie surfaces.

Applications of Direct-to-Food Printer

The versatility of direct-to-food printers has led to a broad range of applications across various sectors:

1. Commercial Food Industry

In the food manufacturing industry, branding and marketing are crucial. Direct-to-food printers enable companies to customize their products with logos, intricate designs, or promotional messages directly onto food items. For example, chocolates with company logos or cakes with personalized messages serve both marketing and customer satisfaction.

2. Culinary Arts and Baking

Chefs and bakers use this technology to push the boundaries of culinary presentation. It allows for creating stunning visual effects that were challenging or impossible with traditional decorating techniques. Custom cakes for special occasions, with complex images or themes, are now more accessible thanks to direct printing.

3. Personalization and Gifting

Consumers increasingly desire personalized food items, especially for celebrations like birthdays, weddings, or corporate events. Direct-to-food printers facilitate quick and easy customization, producing edible images or messages tailored to individual preferences.

4. Food Art and Creativity

Artists and food enthusiasts use this technology as a medium to express creativity. Edible art can include highly detailed photographic images, intricate patterns, or themed decorations, elevating edible presentation to a new level.

5. Food Sampling and Product Testing

Food scientists and researchers use direct printing to create samples with visual markers or branding for testing, marketing, or educational purposes.

Advantages of Using a Direct-to-Food Printer

The adoption of direct-to-food printers offers numerous benefits:

Precision and Detail: The ability to produce highly detailed images ensures food items look visually stunning and uniform, which is essential in high-end patisserie and marketing.

Customization: Each product can be personalized, providing a competitive edge in markets where uniqueness attracts consumers.

Efficiency: Faster than manual decorating or hand-painting, reducing labor costs and time.

Consistency: Ensures

Share:

Direct to food printers for sale

Categories

More Posts

What are the Reasons for the Color Deviation of UV Flatbed Printers?